When it comes to selecting the right excavator bucket OEM manufacturer, there are several crucial factors that construction companies and equipment owners must consider. The quality and performance of an excavator bucket can significantly impact productivity and efficiency on the job site.

Therefore, it is essential to choose a reliable and reputable manufacturer that meets your specific requirements. In this blog, we will discuss key considerations to help you make an informed decision when selecting the best excavator bucket OEM manufacturer.

I. Quality And Durability:

Quality issues are the most important. Because each excavator bucket is for long-term use.

Material Selection:

The choice of materials used in manufacturing the excavator bucket plays a vital role in its quality and durability. Look for excavator bucket OEM manufacturers that utilize high-grade, wear-resistant steel, such as XJCM, to ensure longevity and resistance to abrasion.

Engineering and Design Expertise:

A reputable OEM manufacturer should have a team of skilled engineers who specialize in bucket design. They should consider factors like bucket shape, tooth configuration, and reinforcement techniques to optimize the bucket’s performance and longevity.

Manufacturing Process:

Understanding the manufacturing process employed by the excavator bucket OEM manufacturer is crucial. Look for manufacturers that employ advanced technologies, such as robotic welding and precision cutting, to ensure consistency, accuracy, and strength in the production of their excavator buckets.

II. Customization Options:

Because different types of cranes have different excavator buckets. So you need a mature company (such as XJCM) that can propose solutions for you.

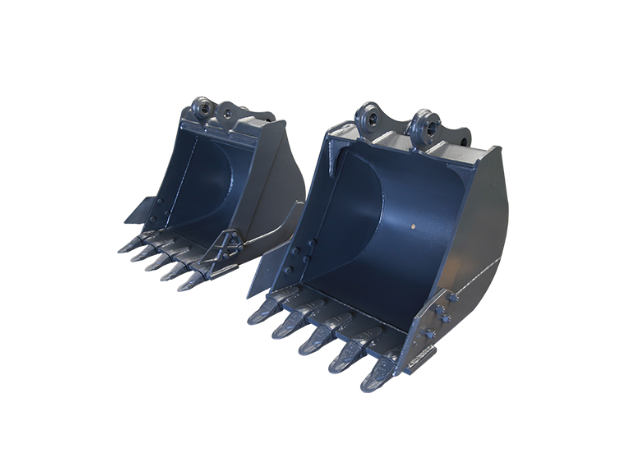

Bucket Types and Sizes:

Different job requirements call for specific bucket types and sizes. A reliable excavator bucket OEM manufacturer should offer a wide range of options to cater to various applications, including general digging, trenching, grading, and rock handling. Ensure the manufacturer can provide customized bucket sizes and configurations to suit your specific needs.

Attachments and Accessories:

Consider manufacturers that provide a range of attachments and accessories, such as teeth, side cutters, wear shrouds, and adapters. These additional components can enhance the performance and versatility of the excavator bucket, allowing it to handle various materials and terrain conditions effectively.

Compatibility with Excavator Models:

Verify that the excavator bucket OEM manufacturer can produce buckets compatible with your specific excavator models. Each excavator has unique specifications and connection requirements, so it is crucial to ensure a proper fit and functionality.

Tooth and Blade Configurations:

The type of tooth and blade configurations on the excavator bucket can impact its performance in various soil or rock conditions. A reputable excavator bucket OEM manufacturer will offer different tooth and blade options, allowing you to optimize productivity and efficiency for different tasks.

For example, XJCM can provide customers with excavator buckets suitable for 2-100 tons of weight. It cuts the drum bottom edge, and plate with wear-resistant material, making it more durable and efficient.

Bucket Design:

Evaluate the design features of the excavator bucket offered by the excavator bucket OEM manufacturer. Look for design elements such as reinforced structures, curved sidewalls, or additional wear protection, which can improve bucket performance and minimize maintenance requirements.

III. Warranty And After-Sales Support:

Whether it is pre-sales or after-sales service, it is very important. If you want to build a long-term and reliable cooperation relationship, it is best to take warranty and after-sales service into consideration.

Warranty Coverage:

A reputable excavator bucket OEM manufacturer should stand behind the quality of their products by offering a comprehensive warranty. Evaluate the warranty duration, coverage of defects, and any specific conditions that may apply.

Customer Support:

Excellent after-sales support is essential for any construction equipment investment. Choose an excavator bucket OEM manufacturer that provides reliable customer support, including technical assistance, spare parts availability, and prompt response to queries or concerns.

Reputation and Reviews:

Research the manufacturer’s reputation in the industry. Check customer reviews, testimonials, and ratings to gauge their overall satisfaction and experience with the OEM manufacturer’s products and services. A excavator bucket OEM manufacturer with a positive reputation is more likely to provide reliable after-sales support.

IV. Pricing And Value For Money:

Cost Considerations:

While pricing should not be the sole determining factor, it is crucial to consider your budget and compare pricing options from different excavator bucket OEM manufacturers. Remember that quality, durability, and performance should take precedence over the lowest price.

Long-Term Investment:

Consider the long-term value and return on investment when evaluating the pricing of excavator buckets. A higher-quality bucket that lasts longer and requires fewer repairs or replacements may prove to be a more cost-effective choice in the long run.

Total Cost of Ownership:

Look beyond the initial purchase cost and consider the total cost of ownership. Factors such as maintenance requirements, operational efficiency, and durability can significantly impact the overall cost of using the excavator bucket over its lifespan.

XJCM: Your Extraordinary Excavator Bucket OEM Manufacturer

To sum up, here we recommend XJCM for you, a manufacturer from China with more than 20 years of manufacturing experience. Below are some reasons to choose XJCM.

Rich Experience in Manufacturing:

With over 20 years of experience in the field of engineering machinery, XJCM has established itself as a trusted excavator bucket OEM manufacturer.

Their expertise extends beyond excavator buckets to include a diverse range of heavy-duty equipment, such as off-road cranes (10-130 tons), truck cranes (12-130 tons), remote-controlled self-erecting tower cranes, self-propelled cable cranes, pipe layers, and customized structural components.

This extensive experience demonstrates their deep understanding of the industry and their ability to deliver high-quality products.

Wide Range of Product Categories:

XJCM’s product portfolio boasts a wide variety of equipment, showcasing their versatility and expertise in different areas of construction machinery.

By offering an extensive range of products, XJCM demonstrates its commitment to meeting diverse customer needs. This comprehensive approach is indicative of their ability to manufacture excavator buckets that align with specific requirements and applications.

Mature Excavator Bucket Manufacturing Technology:

One of the key reasons why XJCM excels in providing excavator bucket OEM services is its mature manufacturing technology. The company has leveraged its years of manufacturing experience to build a strong foundation in excavator bucket production.

This foundation allows them to employ advanced manufacturing techniques and processes, ensuring the highest quality and performance of their excavator buckets.

Final words:

Choosing the best excavator bucket OEM manufacturer requires careful consideration of several key factors. By prioritizing quality and durability, exploring customization options, assessing warranty and after-sales support, and evaluating pricing and value for money, you can make an informed decision.

Remember, selecting a reputable and reliable excavator bucket OEM manufacturer, such as XJCM, will ensure that your excavator bucket meets the demands of your job site and contributes to improved productivity and efficiency. Invest time and effort in finding the right manufacturer, as it will pay off in the long run.